What is Process Control ?

Process control is a vital aspect of industrial operations that involves the use of technology to monitor and regulate various processes within chemical industries. It ensures that manufacturing processes operate efficiently, consistently, and safely by maintaining the desired output within specific limits. Whether it’s controlling temperature, pressure, flow rates, or chemical composition, process control systems enable industries to produce high-quality products while minimizing waste and energy consumption.

An early use of feedback control for manufacturing purposes was by Watt to regulate stream turbines in the late 18th century followed by servomechanisms for ship steering in 1920’s.

James Watt Governor

Why Process Control ?

In the chemical industry, precise control over processes is crucial for several reasons:

Quality Assurance: Ensures that the final product meets the desired specifications, reducing the likelihood of defects and improving customer satisfaction.

Safety: Maintains safe operating conditions, preventing accidents and equipment failures that could lead to hazardous situations.

Efficiency: Optimizes the use of resources such as raw materials, energy, and time, leading to cost savings and enhanced productivity.

Environmental Compliance: Helps in adhering to environmental regulations by controlling emissions and reducing waste, contributing to sustainable operations.

Innovation and Competitiveness: Facilitates the integration of advanced technologies such as AI, machine learning, and predictive analytics, allowing companies to stay competitive and innovate in a rapidly evolving industry.

Capabilities...

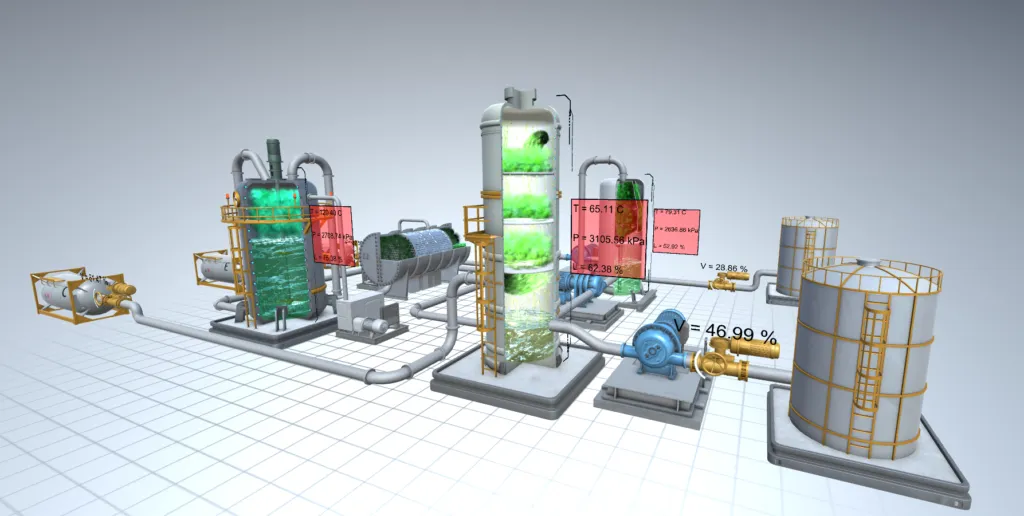

At RPDS, our capabilities in process control are rooted in a deep understanding of both classical and modern control strategies. We excel in implementing advanced process control systems that enhance efficiency, stability, and safety across various industries. Our expertise includes real-time monitoring, process simulation, and control loop optimization, ensuring your operations run smoothly and respond dynamically to changing conditions. By leveraging cutting-edge technologies and data-driven insights, we provide customized solutions that drive performance and reliability in every aspect of your process control systems.

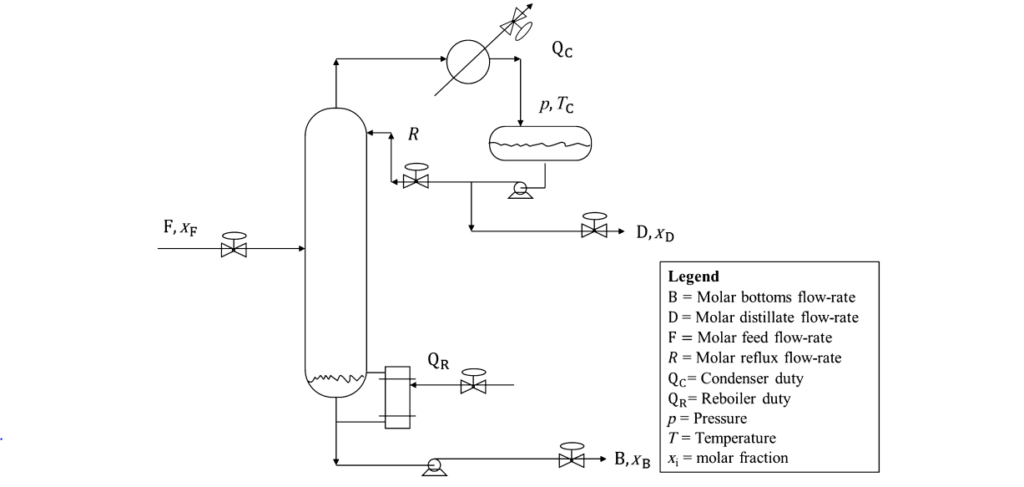

Process Simulation and Modeling

Create accurate models of your processes to predict outcomes and improve control strategies using different modeling approaches like first principle's and data-based

PID Tuning and Control Loop Optimization

Fine-tune PID controllers both model based and online, also optimize control loops for enhanced process stability tuning of the loop

Model Predictive Control

Apply dynamic process models to predict future behavior and optimize control actions, improving efficiency and handling complex systems with multiple variables and constraints.

Multivariable Control

Many of the process measurements respond to many of the manipulated variables. Consequently, multivariable control may be beneficial for reducing interactions

Equipment wise and Plant-Wide Control

Develop integrated control systems that manage and optimize the entire plant, improving coordination and efficiency across all processes.

Estimation/adaptive control

Variation in production rate and product mix may cause the process dynamics to change sufficiently to merit on-line controller adaptation with changing operating conditions